Promotional Features

Innovative dry mill technology produces low carbon-intensity corn syrups

Consumers are increasingly focused on sustainability and the footprint they leave behind for future generations.

Globally, consumers are moving toward sustainable products with a lower carbon footprint or carbon intensity.

A 2021 poll found that 80% of Americans are concerned about the environment.1 That’s up from 74% concerned about the environment in 2019.1

The consumer packaged goods (CPG) industry is at the forefront of the sustainability push, with many companies – all of the top 50 identified by the Consumer Brands Association (CBA) – implementing goals and meaningful, impactful strategies to back them up. Global production of food and consumer goods accounts for 60% of greenhouse gas (GHG) emissions, 80% of water usage, and 66% of tropical forest loss.2 This exemplifies the need to have holistic solutions to increase our efficiency in resource utilization.

CPG brands are looking toward technology innovation, renewable feedstocks and waste reduction strategies to drastically lower carbon emissions as part of their corporate sustainability goals. Brands that are not working to enhance their sustainability could be left behind.

Technology innovation

Refined corn products, whether glucose and dextrose syrups, starches or gluten meal, have traditionally been produced by wet mills, which over decades of operation have continued to optimize the production of these valuable products from corn. So far, the use of dextrose and glucose syrups, whether for food and beverage applications, bioplastics or biochemicals, have relied on the wet mill production processes to help feed the burgeoning demand in biomanufacturing as well as traditional food applications.

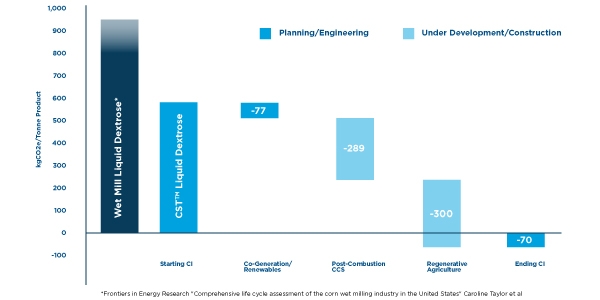

But the wet milling process carries high energy and natural resource requirements, boosting the carbon intensity score of the products it makes. So Green Plains is entering the refined corn ingredient market with a new approach: dextrose and glucose corn syrups from a dry mill, with a carbon intensity (CI) up to 40% lower than traditional alternatives – the lowest CI on the market. This accelerates customers’ decarbonization journeys with a molecularly identical product, with a reduction of up to 350 kilograms of carbon dioxide equivalent per metric ton of corn syrup.

“As part of achieving carbon reduction goals, it’s ingredients that matter,” says Anand Sundaresan, Senior Vice President – Research & Development for Green Plains. “If you have an ingredient that has a lower carbon footprint, that is a much more direct way of reducing the overall footprint of your product.”

Green Plains’ Clean Sugar Technology (CST) is an energy-efficient approach to producing dextrose and glucose syrups at the company’s existing biofuel facilities, utilizing the same corn feedstock. The technology’s advantages are generated from its simple approach in skipping the numerous starch separation and wash steps of the traditional wet mill process. This simplification of manufacturing enables a reduction in water, chemical and electrical usages, leading to an improved carbon footprint for the products.

In further continuing to lower carbon emissions from its processes, Green Plains is focused on sustainability in all its sectors, deploying energy efficiency upgrades, combined heat and power systems, carbon capture technologies, and regenerative agriculture programs, among other measures. That sustainability advantage is passed along to customers, consumers and the planet.

Characteristics of success

The physical attributes of these sustainable dry mill sugar ingredients are equivalent to existing products, lending themselves to be drop-in replacements.

95 DE Unrefined Dextrose Corn Syrup, frequently used as a feedstock in fermentation and other bio-conversion processes, offers high fermentability and conversion yields while providing key growth nutrients to the organisms used in these processes.

95 DE Refined Dextrose Corn Syrup, with a high fermentability and sweetness level, is an ideal feedstock in various fermentation and food manufacturing processes, as well as bio-conversion technologies.

63 DE Refined Glucose Corn Syrup provides a balanced level of sweetness with a lower viscosity in food and beverage products. Its solubility stability and neutral taste profile make it a preferred choice for applications where rapid crystallization control and minimal impact on flavor are essential.

43 DE Refined Glucose Corn Syrup can serve as a sweetness modulator and provide desirable texture and mouthfeel to products such as bakery, confections, and beverages.

In customer evaluations, CST dextrose syrups have outperformed competitors in fermentation trials. These trials have shown equivalent product yield with higher growth rates, leading to increased productivity for the ingredient being produced.

Get green faster

Green Plains’ low carbon-intensity dextrose and glucose corn syrups are ideally suited for food formulations, fermentation and catalytic conversion processes in food and beverage manufacturing, as well as in bio-based materials and renewable chemicals.

One hundred million pounds of low carbon-intensity corn syrup reduces the carbon footprint of a product by up to 12 million kilograms of carbon dioxide equivalent. That carries the same impact as planting 60,000 trees.

Explore how Green Plains can help you get green faster.

References

1. Consumer Brands Association. CPG Outlook 2022: Focus on Sustainability.

2. Consumer Goods Technology. The Sustainability Imperative in CPG.