The fourth degree: Our heat tolerant chocolate doesn’t skimp on taste, says Barry Callebaut

The company says the thermo-tolerant chocolate will appeal to manufacturers operating in warmer climates, such as Asia Pacific or Latin America, where chocolate is liable to melt on shelves.

Identical sensory properties

In 2009, the company introduced a separate concept called Volcano chocolate with a melting point of 55°C. Volcano chocolate is legally recognised as chocolate but the taste is different to a standard chocolate formulation.

“With the new recipes we were looking for B2B thermo tolerant chocolate solutions with characteristics that are comparable to normal chocolate - same workability, sensory, texture, melting behavior in the mouth,” Raphael Wermuth, head of media relations at Barry Callebaut, told ConfectioneryNews.

Ideal for displays in warmer regions

Barry Callebaut introduced the heat tolerant versions for milk and dark chocolate as well as milk and dark compound chocolate.

“The most thermo tolerant prototype we developed melts at about 37.5°C (standard milk chocolate from us melts around 33.5°C),” said Wermuth.

“This improvement will give a benefit when displayed in stores in warmer regions. Yet, we also believe that there is still room for further improvement."

Race for temperature-tolerant chocolate heats up

In 2012, Mondelēz International-owned Cadbury filed a patent for a chocolate that could tolerate hot climates by re-refining the chocolate after the conching step.

Nestlé’s R&D subsidiary Nestec developed its version in 2013 by adding little or no sugar or polyols to the chocolate core and instead adding the humectant liquids to a “tropicalized shell” for the product.

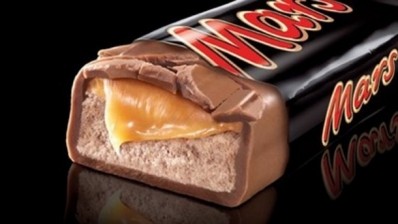

In 2014, Mars filed a patent for a heat tolerant chocolate that involved adding a polyol - preferably glycerin - and a thermal structuring component such as a monosaccharide like dextrose to the formulation.

Hershey filed its own patent in October 2014 for a method that uses‘chocolate dough’ to create a heat stable chocolate without additives or a waxy, dry texture.

Wermuth said that Barry Callebaut's heat tolerant chocolates were obtained by controlled processing and specific ingredients – but would not share further details for competitive reasons.

“These new products can be used for confectionery where the chocolate is the main ingredient. For other applications we might further increase the thermo tolerance,” said Barry Callebaut’s media head.